When constructing or repairing a roof, every component plays a crucial role in ensuring the structure’s longevity and durability. Among these components, roofing nails are often overlooked, yet they are vital for securing shingles, tiles, or metal sheets to the roof deck. A common concern among homeowners and builders alike is whether roofing nails rust over time, potentially compromising the roof’s integrity. This article will explore the factors that influence the rusting of roofing nails, the types of nails available, and how to choose the best nails to ensure a long-lasting, rust-free roof.

The Basics of Roofing Nails

Roofing nails are specifically designed for securing roofing materials to the roof deck. They come in various materials, lengths, and coatings, each offering different levels of durability and resistance to environmental conditions. The primary concern with roofing nails is their exposure to moisture, which can lead to rust—a form of corrosion that weakens the metal, causing it to deteriorate and potentially fail over time.

Why Do Roofing Nails Rust?

Rust is a natural process that occurs when iron or steel is exposed to oxygen and moisture, leading to the formation of iron oxide. Roofing nails are particularly vulnerable to rust because they are often exposed to the elements, including rain, snow, and humidity. The rusting process can be accelerated in certain conditions, such as in coastal areas where salty air increases the rate of corrosion, or in climates with frequent rain or heavy dew.

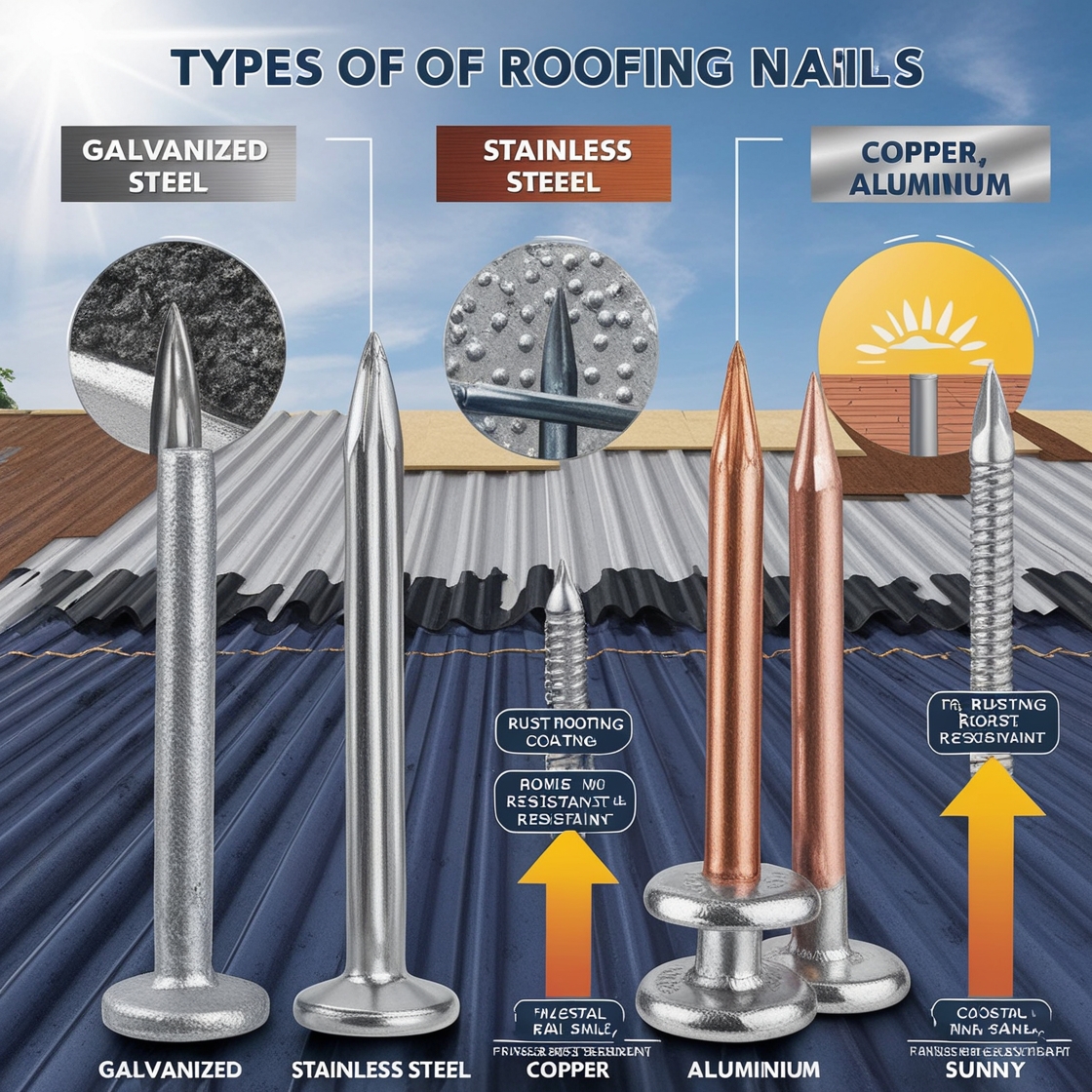

Types of Roofing Nails and Their Resistance to Rust

The extent to which roofing nails rust depends largely on the material from which they are made and any protective coatings they may have. Here’s a breakdown of the most common types of roofing nails and their rust resistance:

1. Galvanized Nails

Galvanized roofing nails are the most commonly used type, known for their rust-resistant properties. These nails are coated with a layer of zinc, which acts as a protective barrier against moisture and oxygen. There are two main types of galvanized nails:

- Electro-Galvanized Nails: These nails have a thin layer of zinc applied through an electroplating process. While they offer some rust resistance, the thin zinc coating can wear off over time, especially in harsh environments, leading to rust.

- Hot-Dipped Galvanized Nails: These nails are coated with a thicker layer of zinc by dipping them in molten zinc. The thick coating provides superior rust resistance, making hot-dipped galvanized nails a better choice for roofing, especially in areas prone to moisture.

2. Stainless Steel Nails

Stainless steel roofing nails are highly resistant to rust and corrosion, making them an excellent choice for long-lasting durability. Stainless steel contains chromium, which forms a passive layer of chromium oxide on the nail’s surface, preventing rust even in harsh environments. These nails are particularly recommended for use in coastal areas or regions with high humidity.

The downside of stainless steel nails is their cost, which is significantly higher than galvanized nails. However, the investment can be worthwhile for homeowners who prioritize long-term protection against rust.

3. Copper Nails

Copper roofing nails are another option with excellent rust resistance. Copper naturally resists corrosion and develops a protective patina over time, which can further enhance its durability. Copper nails are often used in conjunction with copper roofing materials or in historical restorations where maintaining an authentic appearance is important.

However, copper nails can react with certain materials, like aluminum, leading to galvanic corrosion, so they should be used carefully and in appropriate applications. Additionally, copper nails are more expensive than galvanized nails.

4. Aluminum Nails

Aluminum roofing nails do not rust because aluminum does not contain iron. Instead of rusting, aluminum forms a protective layer of aluminum oxide, which shields the underlying metal from further corrosion. These nails are lightweight and resistant to rust, making them a suitable choice for certain roofing applications. However, aluminum nails are not as strong as steel nails and may not be suitable for all types of roofing materials, particularly heavier ones.

Factors That Influence Rusting

Even with rust-resistant nails, several factors can influence the likelihood of rust developing over time:

- Climate and Environment: Roofing nails in humid, rainy, or coastal environments are more prone to rust due to increased exposure to moisture and salt.

- Installation: Improper installation, such as overdriving nails or leaving them exposed, can remove protective coatings or create conditions where water can pool, leading to rust.

- Roof Ventilation: Poor ventilation can lead to condensation buildup under the roof, increasing the moisture exposure of nails and contributing to rust.

- Material Compatibility: Using nails that are incompatible with the roofing material can lead to galvanic corrosion, where two different metals react and accelerate rusting.

Preventing Rust on Roofing Nails

To minimize the risk of rust on roofing nails, consider the following tips:

- Choose the Right Nails: Select nails with appropriate rust-resistant properties for your specific environment. Hot-dipped galvanized or stainless steel nails are generally the best options for most roofing applications.

- Proper Installation: Ensure nails are driven to the correct depth, not overdriven or under driven, and are not exposed unnecessarily.

- Regular Inspections: Periodically inspect your roof for any signs of rust or corrosion, especially after severe weather conditions.

- Consider the Environment: In coastal or high-humidity areas, prioritize nails with higher rust resistance, even if they come at a higher cost.